Capabilities

Our capabilities include a full CNC machining division that boasts up to 8-axis CNC Turning and 5-axis CNC Milling, empowering us to bring any part to life with precision and efficiency. From intricate components to complex designs, our advanced machines and skilled machinists ensure unparalleled results.

To demonstrate the scope of Rainhouse’s CNC capabilities, some examples of our recent projects include:

Remanufacturing legacy parts for military training fighter jets

Remanufacturing (CCI) military radar chaff device coolant pump

Semi-conductor production equipment (a vital component in many electronic devices)

Production of a wearable medical device to help treat the symptoms of Lyme disease

Instrument racks to hold and organize various instruments and devices for submarine communications rooms

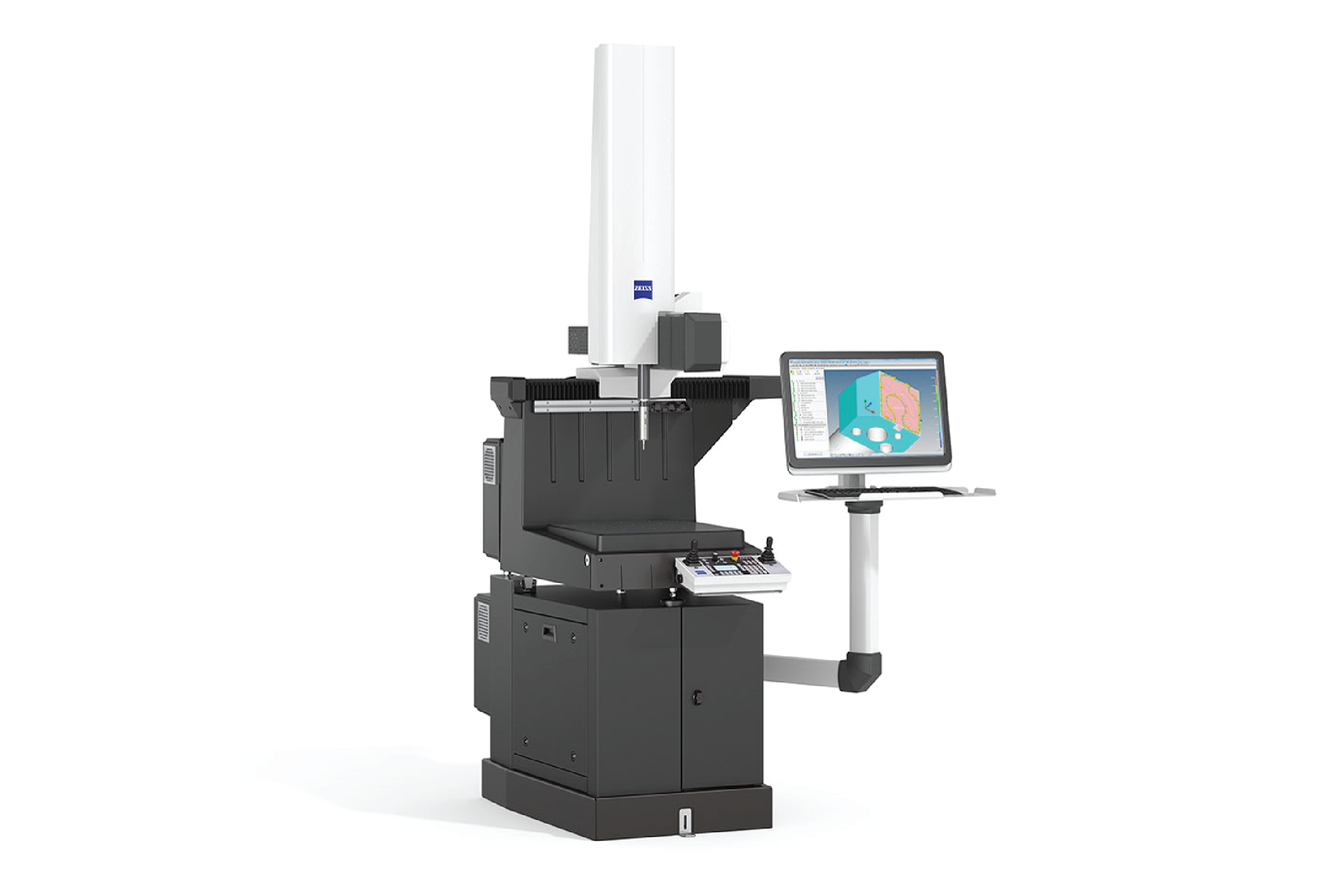

Third-party inspection of large marine driveline parts for accuracy and compliance with industry standards using a fully automated CMM

We love design and manufacturing challenges

Puma 240M

- Max. Turning Diameter: 350mm

- Max. Turning Length: 439mm

- Spindle Speed: 6,000 RPM

Matsuura MX-520

- Work Envelope mm(in)

- 520 x 350H(20.47×13.77H) | 710 x 350H (27.95×13.77H) *with conditions

- Spindle Speed: 12,000 RPM

Hitachi Seiki VS40

- X-Axis: 600mm

- Y-Axis: 450mm

- Z-Axis: 450mm

- Spindle Speed: 12,000 RPM

Hitachi Seiki VS50

- X-Axis: 1000mm

- Y-Axis: 510mm

- Z-Axis: 450mm

- Spindle Speed: 12,000 RPM

Fanuc Robodrill D21MiB5adv

- X-Axis: 500mm

- Y-Axis: 400mm

- Z-Axis: 400mm

- Spindle Speed: 12,000 RPM

Fanuc Robot M-10iD/12

- Payload: 12KG

- Controlled Axes: 6

- Reach: 1441mm

Zeiss Duramax

- X-Axis: 500mm

- Y-Axis: 500mm

- Z-Axis: 500mm

- Software: Zeiss Calypso

Made to Measure Blackhawk

- X-Axis: 600mm

- Y-Axis: 800mm

- Z-Axis: 500mm

- Software: Renishaw’s MODUS

Videojet 7310

- Power Class: 20W

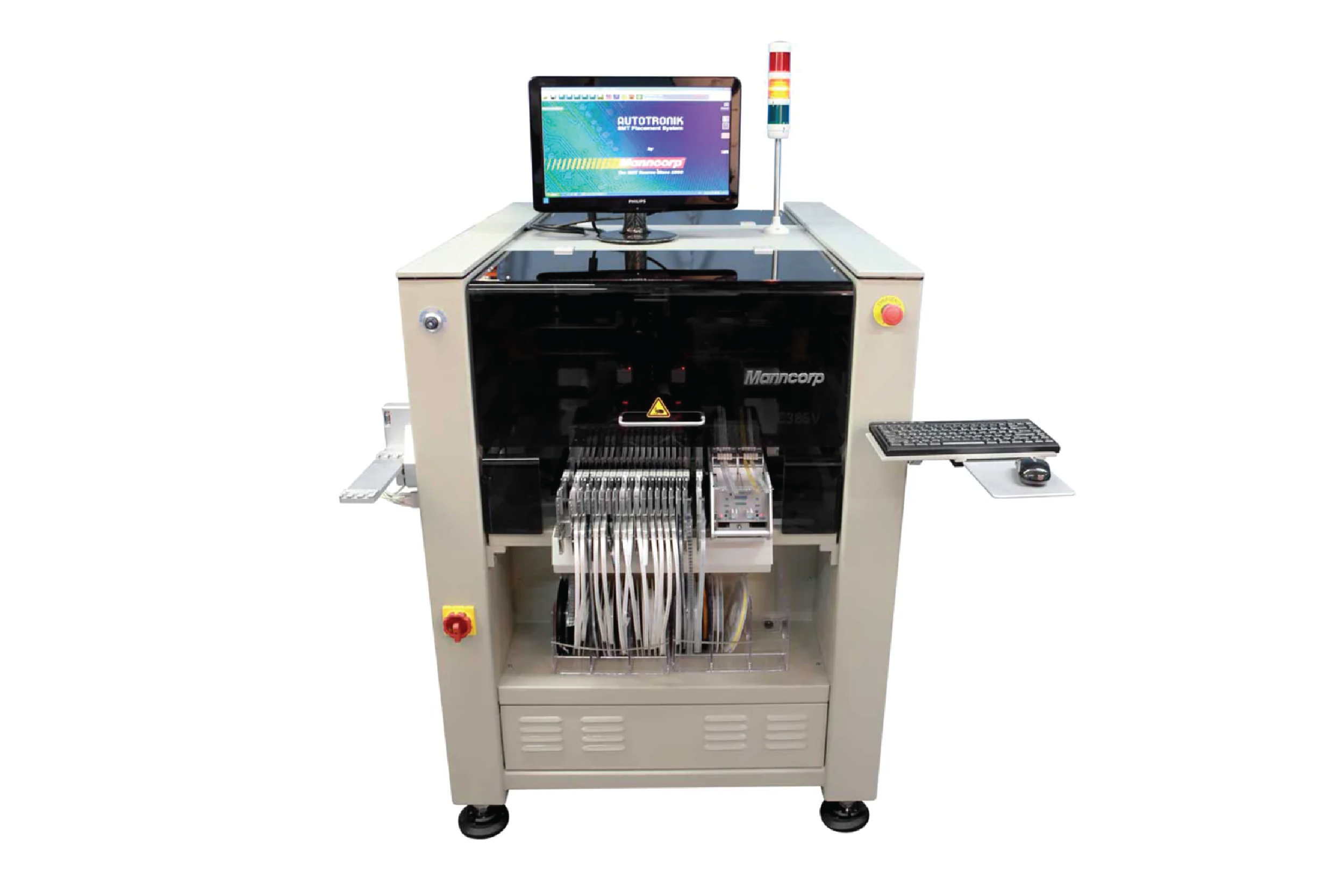

Manncorp MC385V2V

- Work Envelope mm(in): 350×435(13.8×17.1)

- Placement Rate (IPC-9850): 5,500 CPH