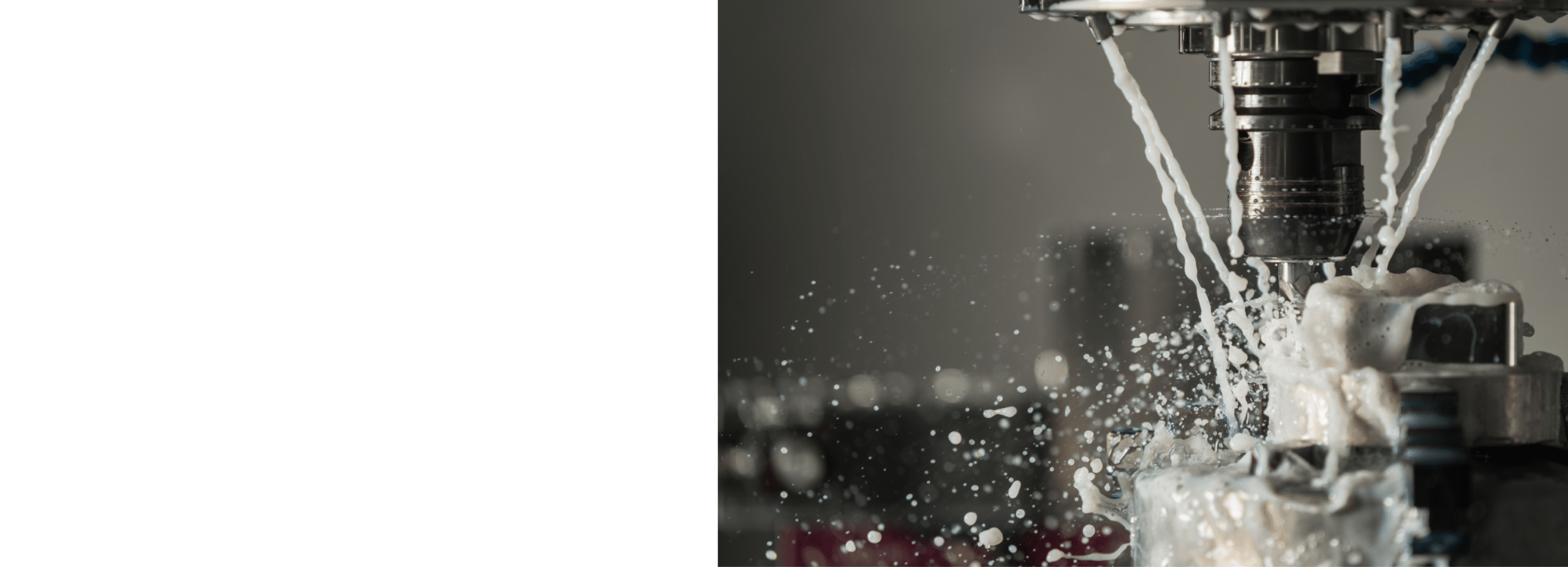

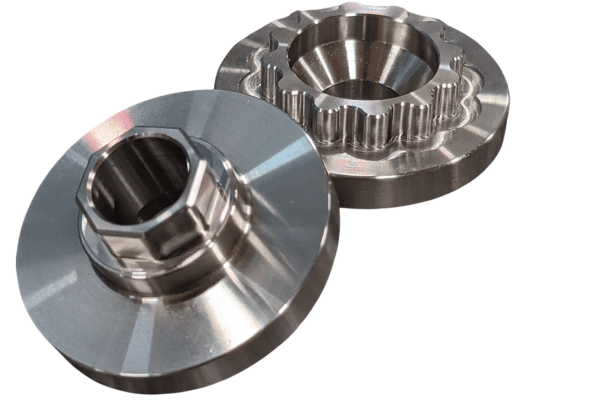

CNC Milling

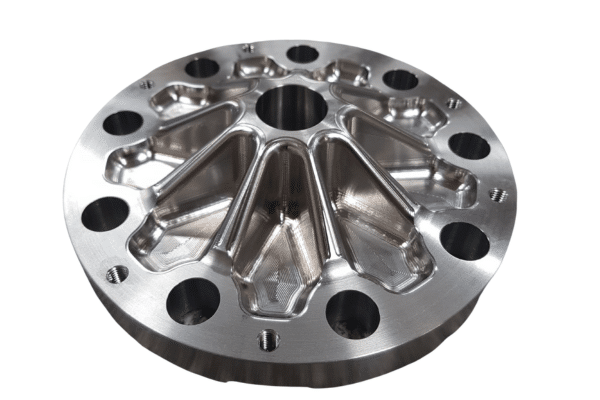

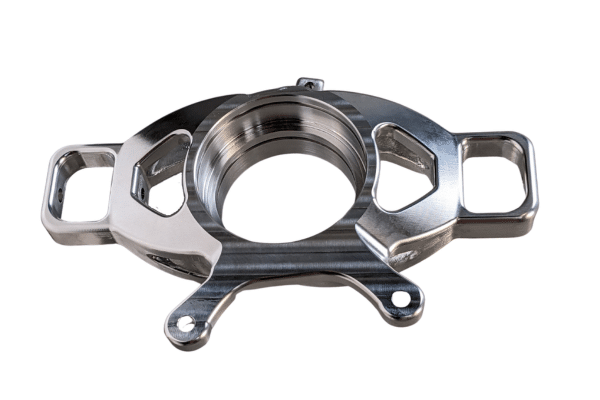

CNC milling is a game-changer in the manufacturing industry, delivering faster, more precise, and highly efficient production of intricate parts and components. With its advanced capabilities and computer-controlled precision, CNC milling has become a crucial process for creating complex geometries and achieving tight tolerances, making it an indispensable tool for modern manufacturing.

What is CNC Milling?

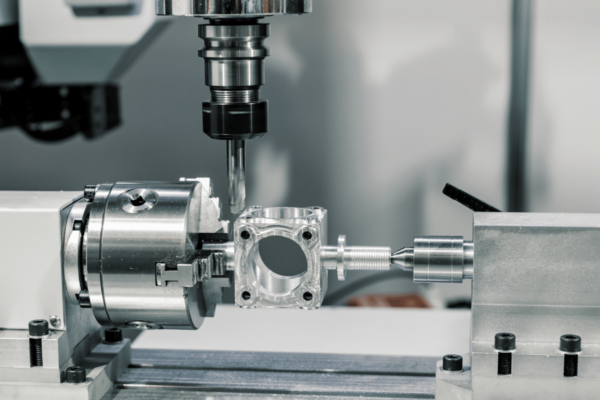

CNC milling is a versatile and precise manufacturing process used to create custom-designed parts and components. During this process, a cutting tool removes material from a solid block of material, commonly known as a workpiece, to achieve the desired shape and specifications.

The process begins by loading a CAD (computer-aided design) model into a CNC (Computer Numerical Control) milling machine. The CNC machine then uses a range of cutting tools to precisely shape the workpiece according to the specifications of the CAD model. CNC milling is renowned for its ability to produce intricate and complex parts with high accuracy, making it an essential method for various industrial applications.

What is a CNC Milling Machine?

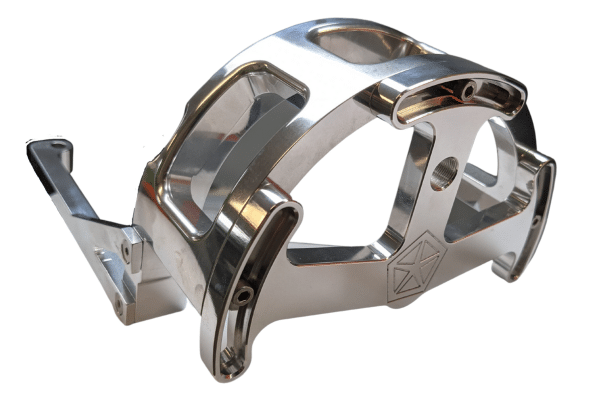

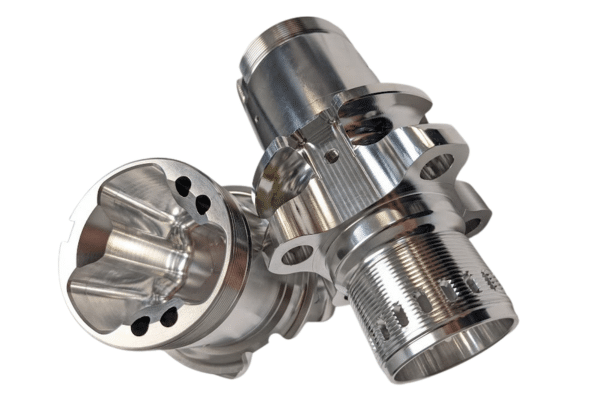

CNC milling machines are sophisticated tools that utilize precise measurements and controlled movements to achieve the exact specifications of a design. These machines operate in various directions, including the traditional X, Y, and Z axes, along with additional rotational axes, enabling the creation of intricate and precise shapes. With the capability to produce parts with incredibly tight tolerances, CNC milling machines are highly sought after in industries that demand the utmost precision, such as aerospace, medical, marine, and defence.

One of the key advantages of CNC milling machines is their efficiency in high-volume production. They can produce parts in significant quantities while maintaining consistent quality throughout the entire batch, making them ideal for high-volume manufacturing scenarios. In summary, CNC milling machines are invaluable tools for achieving precision, complexity, and efficiency in the manufacturing process, empowering industries to create high-quality products that meet the most demanding standards.

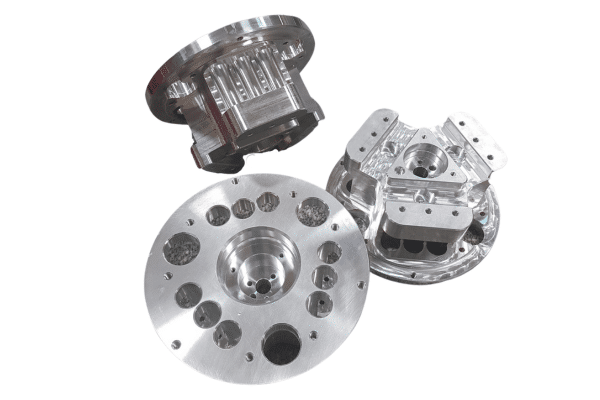

Rainhouse CNC Milling Capabilities

Our full CNC capabilities encompass up to 5-axis CNC milling machines.

Discover the technical details of our advanced CNC milling machines below.

Matsuura MX-520

Work Envelope mm(in):

520x350H(20.47×13.77H)|

710x350H (27.95×13.77H)*with conditions

Spindle Speed: 12,000 RPM

Hitachi Seiki VS40

X-Axis: 600mm

Y-Axis: 450mm

Z-Axis: 450mm

Spindle Speed: 12,000 RPM

Hitachi Seiki VS50

X-Axis: 1000mm

Y-Axis: 510mm

Z-Axis: 450mm

Spindle Speed: 12,000 RPM

Fanuc Robodrill D21MiB5adv

X-Axis: 500mm

Y-Axis: 400mm

Z-Axis: 400mm

Spindle Speed: 12,000 RPM

Fanuc Robot M-10iD/12

Payload: 12KG

Controlled Axes: 6

Reach: 1441mm