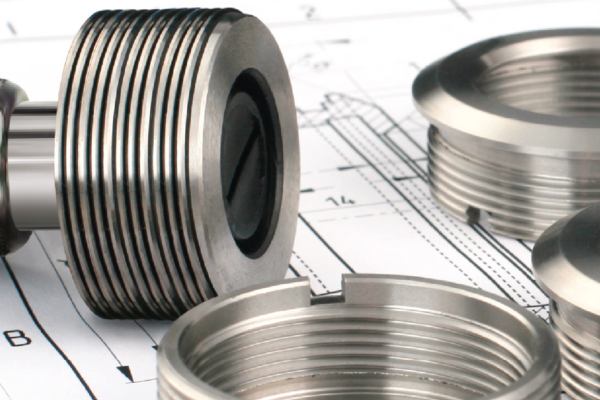

Quality Assurance

Quality assurance services are of utmost importance to Rainhouse. Our ISO 9001:2015 certified quality management system guarantees that every product we make will meet your requirements. Our inspection report will be as detailed as you require.

Quality Assurance Services

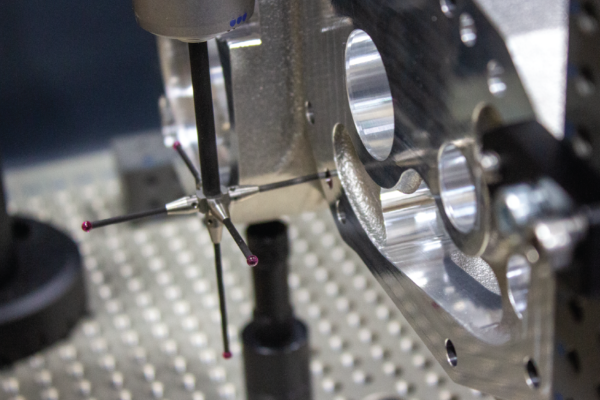

The Rainhouse quality assurance team plays a vital role in our machine manufacturing process. Our quality technicians ensure that every CNC product leaving our shop meets ISO certification requirements and adheres to strict tolerances. We take pride in our Canadian Controlled Goods registration, ISO 9001:2015 certification, and Class MA Boiler and Pressure Vessel License (License No.: LPB0201365), which reflect our commitment to maintaining the highest standards in our operations. Additionally, our quality assurance capabilities include advanced Coordinate Measuring Machine (CMM) technology. This technology enables precise and accurate measurements of complex parts to further enhance the quality control process.

Quality Assurance is Our Number One Priority

Quality is our top priority. To ensure that our production process creates parts that conform to customer requirements, we conduct First Article Inspections (FAIs). Throughout the manufacturing process, our quality technicians collaborate with CNC machinists for In Process Checks (IPCs) to maintain exceptional quality control. We provide a Certificate of Conformance (CoC) for every batch of parts, assuring customers of their compliance. Additionally, Material Traceability Certifications (MTCs) are included with all CNC machined parts to enhance traceability and compliance.

At Rainhouse, our commitment to delivering top-quality products and services makes us the trusted partner for all your CNC machining needs.

Third-Party Quality Assurance Services

Rainhouse extends its services to include third-party quality assurance inspections for parts produced by other manufacturers. While inspection reports are not automatically generated, we offer the option to provide printed or digital reports upon request. These reports can contain precise measurements, as specified in the part drawing, for at least one part from the batch, demonstrating compliance with the required specifications.