Research & Development

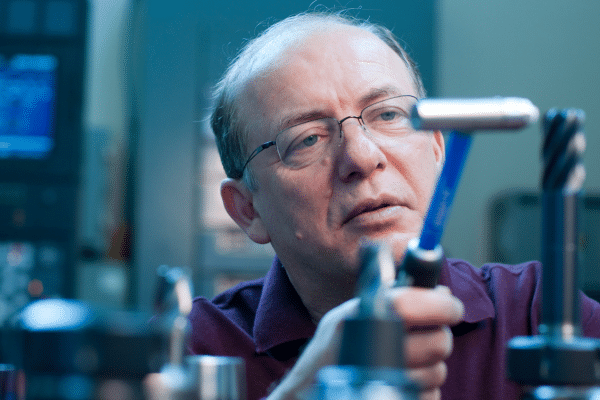

As a big believer in innovation, Rainhouse has established an in-house research and development (R&D) department.

By investing in R&D, we continuously drive innovation, ensuring we remain at the forefront of cutting-edge solutions.

CANRIMT

Created by Rainhouse’s R&D department in collaboration with The University of British Columbia, NSERC, and academic and industry collaborators across Canada

The CANRIMT project aims to transform traditional machining by developing a next-generation smart manufacturing platform that integrates digital twin technologies, physics-based models, artificial intelligence, and real-time data acquisition systems.

Anti-Vibrational Control System – AVCS

Created by Rainhouse’s R&D department.

Rainhouse continues its efforts to invest, research, and collaborate. Our Anti-Vibration Control System project aims to develop a sensor that will measure vibrations within a machine tool to improve the quality and optimize the process to create parts.