Rainhouse is proud to support advanced manufacturing research through the CANRIMT initiative. This collaboration aims to advance digital twin technologies and enhance machine tool performance in Canadian aerospace and manufacturing sectors.

Canadian Network for Research and Innovation in Machining Technology (CANRIMT)

Project Overview

Project name:CANRIMT (Canadian Network for Research and Innovation in Machining Technology)

In partnership with: The University of British Columbia, NSERC, and academic and industry collaborators across Canada

Type of project: Manufacturing Research and Innovation

Industry: Advanced Manufacturing / Aerospace

Phase: Ongoing (as of 2024)

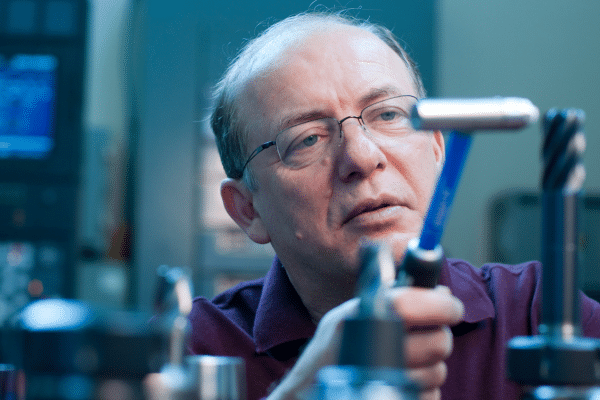

Advancing CNC capabilities through research and industry collaboration.

The Problem

Modern machining systems often lack the flexibility, adaptability, and real-time responsiveness required to meet the rigorous demands of advanced manufacturing sectors such as aerospace, defense, and medical. Manufacturers continue to face persistent issues related to tool wear, machine inefficiencies, and costly downtime. At the same time, the full potential of digital twin technology and data-driven optimization remains untapped in many production environments. These challenges hinder innovation, limit productivity, and increase costs across the Canadian manufacturing landscape.

The Project Goal

The CANRIMT project aims to transform traditional machining by developing a next-generation smart manufacturing platform that integrates digital twin technologies, physics-based models, artificial intelligence, and real-time data acquisition systems. The goal is to improve machining performance through adaptive control strategies and intelligent tool monitoring, enabling more efficient, reliable, and high-quality production processes.

Project Benefits

CANRIMT will deliver a significant leap forward in smart manufacturing by enabling precision control, reducing production waste, and increasing tool life through real-time monitoring and predictive analytics. The outcomes will directly support Canada’s manufacturing ecosystem by enhancing competitiveness, supporting the adoption of Industry 4.0 technologies, and creating new capabilities for companies operating in high-performance sectors. The platform’s ability to integrate with a wide range of CNC machines also ensures scalability and broad industrial impact.